Slurry Transport System

Slurry Transport System (STS)

STS is a muck transport system for tunnel construction that uses a slurry-type Tunnel Boring Machine (TBM). The system circulates the slurry into the TBM’s chamber to stabilize its face against earth and water pressure from the ground. The slurry then mixes with excavated muck, and then gets pumped out of the shaft for treatment.

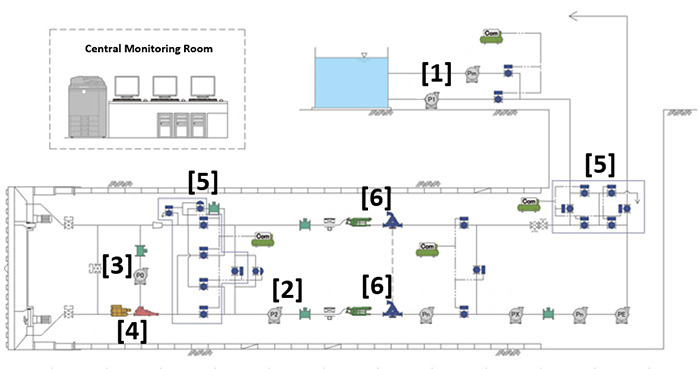

STS Flow

[1] Slurry Feed Pump

P1 Pump, powered by a variable speed motor, controls the tunnel-face pressure. An additional PM pump may be installed to assist maintaining the tunnel-face pressure while excavation is halted.

[2] Slurry Discharge Pump

P2 pump sends out a mixture of muck and slurry. Additional PE, PX, and Pn pumps may be installed to assist controlling the discharge flow rate.

[3] Circulation Pump

P0 pump maintains the flow of the circulation system. Flowmeters along the circulation system allow precise control of the pump’s revolutions per minute (RPM).

[4] Gravel Processor

Bigger gravel within the fluid can clog the pipelines and pumps. The gravel crusher will process this gravel into a smaller size to minimize this concern.

[5] Valve Set

The automatic valve unit inside the tunnel will operate bypaths and circuits, while a shaft-bottom valve set is used for adding pipes and assisting bypaths at the shaft. Both valve sets operate by compressed air.

[6] Pipeline Extension Device

A 3-way rotary valve stops the slurry flow during the pipeline extension to prevent slurry leakage. The hose-reel unit is also used to allow continuous circulation of slurry while an excavation is in progress.

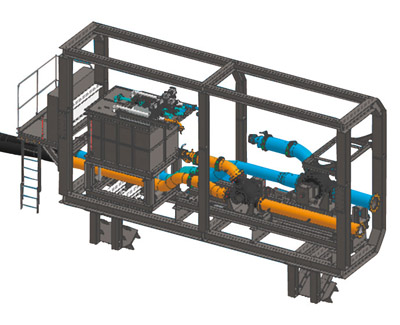

Sample Design (Subsequent Car)

We design and manufacture modules as well!

• We design and manufacture frames, equipment, and an installment plan based on the rental machine’s usage.

• Total support on provisional facilities with our machine.

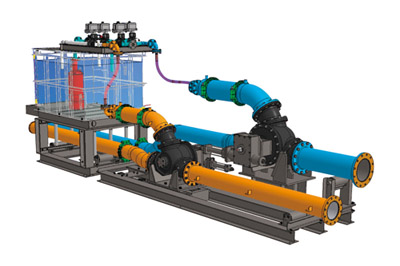

Slurry Pump

•Abrasion resistant

•Improved discharge/power efficiency

3-way Rotary Valve Set

• Allows leak-less extension of pipes for slurry type shield tunneling.

• Will design as either a self-propelled or on wheels, depending on customer’s request.

System Abstract

During pipeline extension, the three-way valve will block the slurry’s flow from the tunnel’s face by switching the main outflow line to a plug line. The submerged pump in the water tank will send the plug (the pig) towards the shaft-side of the line, thus blocking the slurry from the face and assisting the extension of the pipeline. The pump is equipped with magnetic sensors to detect the plug’s passing and arriving point, and can automatically send and return the plug.

*This equipment must be used with a shaft-bottom valve set.

*The water used for sending the plug must be processed by vacuum equipment, or disposed as wastewater.

Specifications

■Slurry Pump

| Product Code | KP2 10000 002 | KP2 15000 002 | KP2 20000 002 | KP5 10000 001 | KP5 15000 001 | KP5 20000 001 | KP6 20000 001 | KP6 30000 001 | KP6 35000 001 |

|---|---|---|---|---|---|---|---|---|---|

| Maker | Furukawa Industrial Machinery Systems Co., Ltd. | ||||||||

| Frequency (Hz) | 50/60 Dual Purpose | ||||||||

| Model | SPD2- 100 |

SPD2- 150 |

SPD2- 200 |

SPD5- 100 |

SPD5- 150 |

SPD5- 200 |

SPD6- 200 |

SPD6- 300 |

SPD6- 350 |

| Diameter (mm) |

100 | 150 | 200 | 100 | 150 | 200 | 300 | 350 | |

| Dispense Amount (m3/min) |

1.4~ 4.0 |

3.0~ 8.0 |

5.0~ 14.0 |

1.4~ 4.0 |

3.0~ 8.0 |

5.0~ 14.0 |

5.0~ 15.0 |

10.0~ 25.0 |

15.0~ 33.0 |

| Head (m) |

45 | 55 | 50 | ||||||

■High Grade Liner Slurry Pump

| Maker | Furukawa Industrial Machinery Systems Co., Ltd. | |||

|---|---|---|---|---|

| Model | LX-300C | LX-350C | ||

| Frequency | (Hz) | 50/60 Dual Purpose | ||

| Intake Diameter | Discharge | (mm) | 350 | 400 |

| Diameter | (mm) | 300 | 350 | |

| Head | (m) | 70 | ||

| Discharge Amout | (m3/min) | 45 | 60 | |

| Max. RPM(min-1{rpm}) | 700 | 640 | ||

| Max. Grain Size | (mm) | 85 | 100 | |

| Bearing Grease | Turbine Oil VG68 | |||

| Mass | (kg) | 8,000 | 10,000 | |

| Max. Efficiency (Pure Water) | (%) | or more | ||

FAQ

Contact Us

AKTIO Corporation – Engineering Department:

Address: Tokyo DL Center 4F, 3-6-41 Shinsuna, Koto-ku, Tokyo, 136-0075